- Privacy Policy

We respect the privacy of every individual who visits our website. We do not sell or rent your personal information to third parties for marketing purposes. Please read this Privacy Policy carefully to learn more about the ways in which we use and protect your personal information. By visiting our website, you are accepting the practices described in this Privacy Policy.

If you visit our website: In general, you can visit our website without telling us who you are or revealing any personally identifiable information about yourself. Our web servers collect the domain names, not the e-mail addresses, of visitors.

In some cases, we may collect information about you that is not personally identifiable. This information is collected using a “cookie” that enables us to learn which advertisements bring users to our website. Cookies are small files placed on your hard drive that allow us to collect that information. We use this information to help us manage online advertising. None of the information collected by a cookie is personally identifiable, i.e., does not contain your name, address or e-mail address.

We may utilize a third party to track and analyze usage and volume statistical information from our website customers in order to constantly improve the quality of our website. No data collected by a third party on behalf of this site may be owned or used by such third party. We reserve the right to publish nonpersonally identifiable, summary information regarding its website customers for promotional purposes and as a representative audience for advertisers.

If you choose to identify yourself: If you voluntarily provide us with personally identifying information, such as your name, street address, email address, phone number, and birth date, we will collect that information along with any other information you voluntarily provide.

It is our policy not to distribute, sell, rent or in any way make available, your name, e-mail address or any other personally identifiable information to any third party.

When you participate in site features such as newsletters, etc., we may use the personally identifiable information you provide through those features in the following ways, unless stated otherwise:

- We may store and process that information to better understand your needs and how we can improve our products and services, and

- We may communicate with you via e-mail or postal mail.

Deletion of Personal Information

If at any time you do not wish to have your personal information collected, you may cancel your membership through our website. You may access, update, or cancel your membership on our website at any time. Upon cancellation, all of your personal information will be deleted from our system.

Children’s Online Privacy Protection Act

We have no intention of collecting any personally identifiable information (name, address, telephone number, birth date, or e-mail address) from individuals under 13 years of age. If a child has provided us with personally identifiable information, a parent or guardian of that child should contact us at the e-mail address or phone number listed at the bottom of this Statement if they would like this information deleted from our records. We will use reasonable efforts to delete the child’s information from our existing files.

Policy Changes

We may, at any time, amend the provisions in this Privacy Policy.

- Products

Modular Air-to-Water Heat Pumps

Jetson Air-to-Water Heat Pump units are air-source refrigeration units with the ability to produce chilled or heated fluid with one refrigerant-to-water heat exchanger. A refrigerant reversing valve is used to switch between cooling and heating modes.

View More

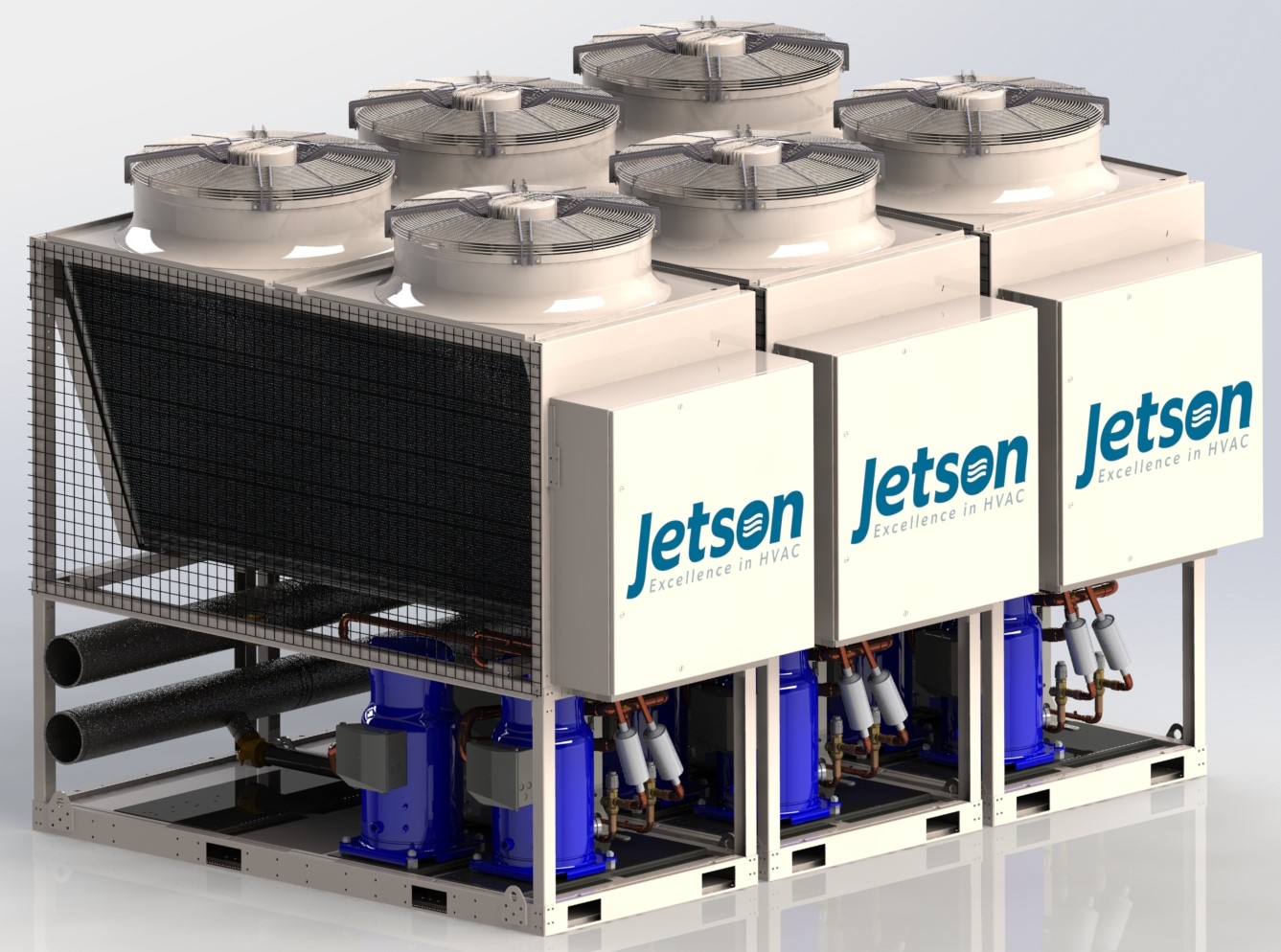

Modular Air-Cooled Chillers

Jetson Modular Air-Cooled Chillers feature an industry leading small-footprint, modular design that makes them ideal for easy replacement, retrofit, or new construction applications…

View More

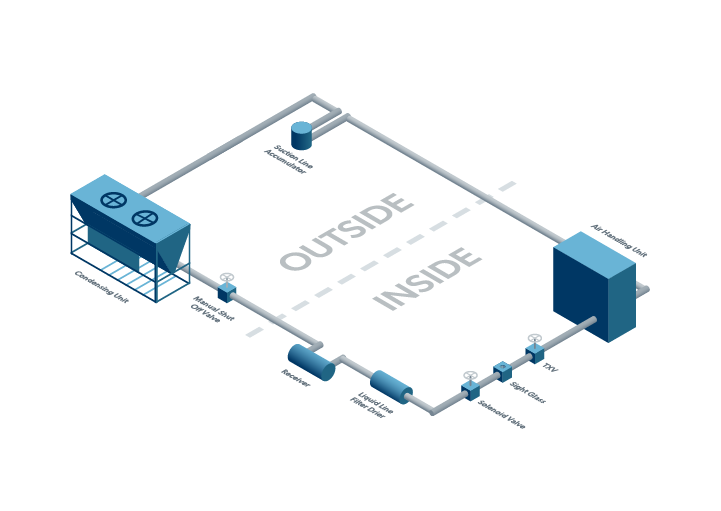

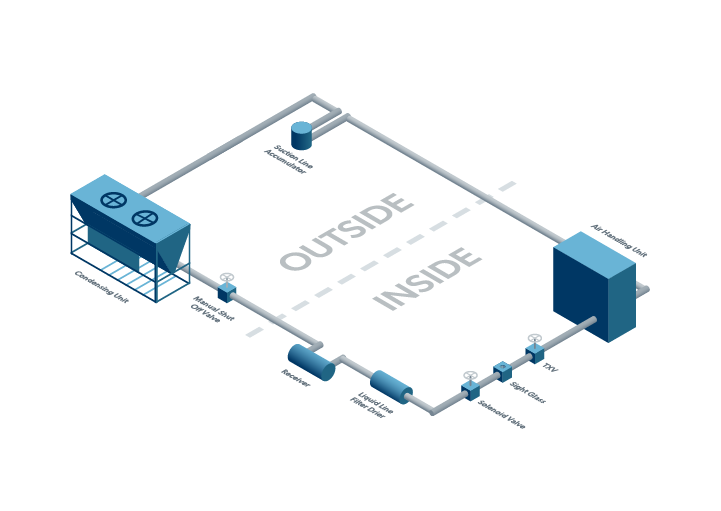

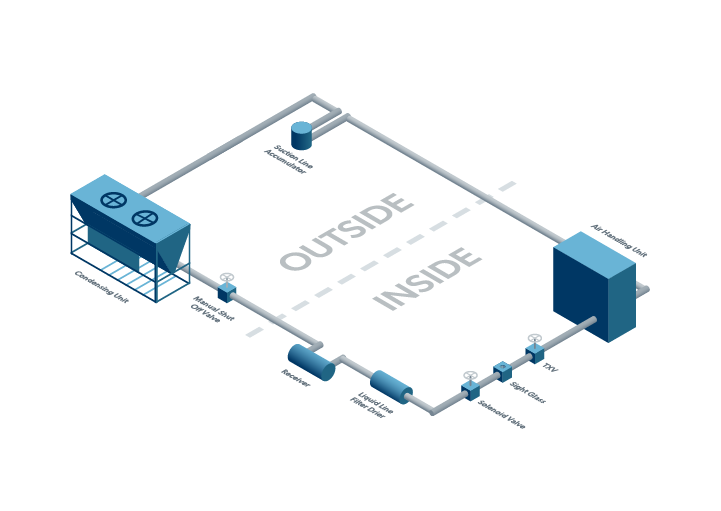

Air-Cooled Condensing Units

Jetson Air-Cooled Condensing Units are the leaders in the split system marketplace. Designed for efficiency, reliability and flexibility, the Jetson units have the most advanced design in the industry…

View More

Split-System Air-Cooled Chillers

Jetson Split-System Air and water Cooled Chillers, Condensing Units and Condensers are designed for the high demands of the split system market. Designed for efficiency, reliability and serviceability…

View More

Modular Water-Cooled Chillers

Jetson Modular Water-Cooled Chillers feature a compact modular design that makes them ideal for easy replacement, retrofit, or new construction applications. Modular chillers offer superior expandability for future expansion…

View More

Packaged Water-Cooled Chillers

Jetson Packaged Water-Cooled Chillers are engineered for quiet, reliable, and high efficiency performance. They are equipped with brazed plate evaporators and robust shell and tube condensers

View More

Air-Cooled Compressor Chillers

Jetson Compressor Chillers are a remote condensing solution designed for the high demands of the split system market. They suit educational, healthcare, office, municipal, and light industrial applications.

View More

Water-Cooled Condensing Units

Jetson Water-Cooled Condensing Units are designed for quiet, high efficiency operation and built to withstand demanding continuous duty cycles. Water-cooled condensing units are shipped with a dry nitrogen holding…

View More- Modular Water-Cooled Chillers

Features & Options

- Modular capability to install up to ten (10) modules together to reach capacities up to 600 tons

- ASHRAE 90.1 compliant

- Intuitive, factory installed microprocessor-based controller compatible with BACnet®, Modbus®, and LonTalk®

- Single circuit refrigeration systems for lower first costs or dual circuit refrigeration systems for greater operating redundancy

- Heat Recovery capability up to 140°F (60°C) to conserve energy by reusing condenser leaving water to serve heat loads like boiler loops, reheat coils and more

- High and low-pressure protection/compressor overload protection

- Single point electrical connection for array or separate module electrical feeds provide electrical redundancy

- Shipped with R-454B for water-cooled systems or nitrogen holding charge for split systems

- Designed for easy retrofit—fits through a standard three-foot door

- Factory-assembled and shipped with complete internal piping and wiring, essential controls and protective devices

- Compressors are factory installed on rubber isolation mounts for quiet operation

- Compressor acoustic hoods and/or sound isolating cabinets are available for sound sensitive applications

- Simple to use controls with displays in plain English and automatic data logging of faults and alarms

Applications

- High capacity evaporators are available for 40°F (4°C) leaving water applications or for applications requiring glycol to offset capacity reduction of glycol system.

- Water-cooled, remote air-cooled, or evaporative condenser applications.

- Constant or variable primary flow systems with factory provided valve packages.

- N+1 or N+2 redundant control logic.

- Ice making mode available for skating rinks, thermal storage, and more.

- Designs for 150 psi or 300 psi water pressure applications.

Resources

- Water-Cooled Condensing Units

Features & Options

- Capacities from 20 to 75 tons

- Designed for easy retrofit—fits through a standard three-foot door

- Brazed plate condenser for high efficiency or shell and tube condenser for robust design

- Intuitive, factory installed microprocessor-based controller compatible with BACnet®, Modbus®, and LonTalk®

- Labeled control wiring matches unit wiring diagram included in the control compartment

- Compressors are factory installed on rubber isolation mounts for quiet operation

- Replaceable core filter driers for ease of service and installation of split system piping

- Compressor acoustic hoods and/or sound isolating cabinets are available for sound sensitive applications

- LED lighted control cabinet for clear viewing during service and maintenance

- Water-cooled condensing units provide great design flexibility because they can be combined with a wide variety of coils or chillers

- 15.4” Touchscreen for viewing machine performance and easy access for service and maintenance personnel

- Fused or non-fused disconnect switches are available factory installed

- R-454B available

Applications

- Water-cooled condensing unit can be applied where air cooled units are not desirable or space is unavailable.

- The Jetson water-cooled condensing units can be paired with remote direct expansion (DX) air handlers or remote chilled water evaporators for design flexibility.

Resources

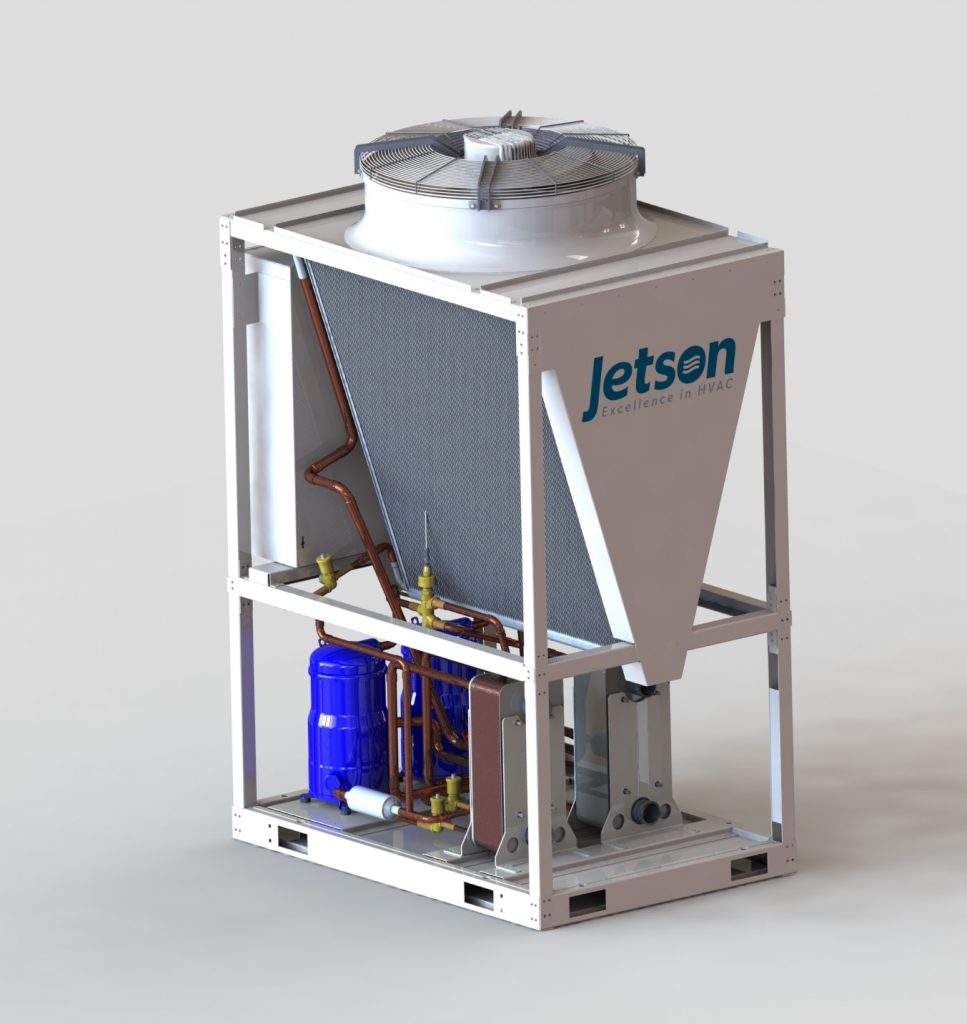

- Modular Air-to-Water Heat Pumps

Features & Options

- Reverse cycle heat pumps allow for elimination of boiler systems by allowing the chiller to provide hot water for heating demand

- Heat pumps are available in 10 through 80-ton standalone units and can be combined in modular assemblies for up to 240 tons per array

- High efficiency scroll compressors and liquid injection scroll compressors available

- Air-To-Water Heat Pumps equipped with liquid injection compressors can generate up to 130°F (54°C) hot water at a 0°F (-17°C) ambient temperature and are designed to operate effectively in ambient temperatures as low as -10°F (-23°C).

- Two-pipe or Four-pipe configuration

- Four-pipe operation with brazed plate condenser sized for full heat recovery offers significantly more heating capacity than a desuperheater

- Heat recovery option can provide 140°F (60°C) hot water to reheat dehumidified buildings, pre-heat laundry or pool water

- Loop switching valves and modular hot water pipes factory installed.

- Standard uncoated or optional e-coated microchannel heat exchanger (MCHE) condenser coils for a better efficiency during defrost mode and a reduced refrigerant charge

- Highly efficient, dual circuit brazed plate heat exchangers offer maximum performance at both full and part-load conditions.

- Intuitive, factory installed microprocessor-based controller compatible with BACnet®, Modbus®, and LonTalk®

- Galvanized steel frame with painted epoxy finish on exterior panels minimize corrosion and promote long equipment life

- Ground or rooftop installation

- Compressors are factory installed on rubber isolation mounts for quiet operation

- Compressor acoustic hoods and/or sound isolating cabinets are available for sound sensitive applications

- ASHRAE 90.1compliant

- R-454B available

- UL 60335 compliant for R-454B refrigerant

Modes of Operation

- Cooling Mode: The refrigerant-to-water heat exchanger is the energy source for the refrigeration circuit, absorbing heat from the chilled water. The refrigerant-to-air coil is the energy sink, rejecting heat to ambient air.

- Heating Mode: The refrigerant-to-air heat exchanger is the energy source in the circuit, absorbing heat from the outdoor air, while the refrigerant-to-water is the energy sink in the circuit, rejecting heat to the heating water circuit.

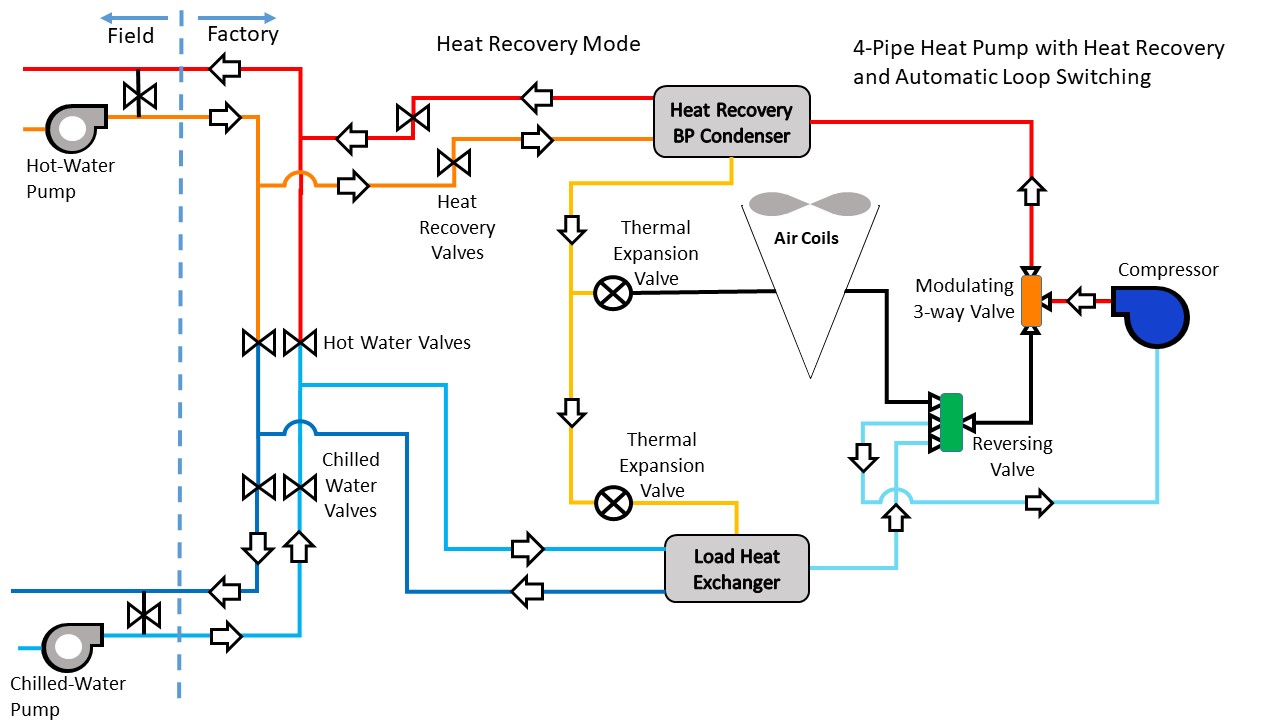

- Heat Recovery Mode: Heat pumps typically feature a single-load refrigerant-to-water heat exchanger capable of either cooling or heating, but not both simultaneously. With the addition of a heat recovery option, a second refrigerant-to-water heat exchanger is incorporated alongside the load heat exchanger. This secondary heat exchanger is designed to heat a separate fluid loop while the primary load refrigerant-to-water heat exchanger is in cooling operation. (4-pipe system + Heat Recovery Option)

2-pipe Air-to-Water Heat Pump

Reverse cycle (heat pump) chiller with heat recovery capability Resources

- Modular Air-Cooled Chillers

Features & Options

- Modular capability to install up to ten (10) modules together to reach capacities up to 800 tons

- Flexible side-to-side configurations (see images) provide footprint flexibility for even challenging installations

- Compressors are factory installed on rubber isolation mounts for quiet operation

- Compressor acoustic hoods and/or sound isolating cabinets are available for sound sensitive applications

- Variable speed compressors and condenser fans

- ASHRAE 90.1 compliant

- Hydronic pump package are available skid mounted

- Reduced refrigerant charge to help earn LEED EA credit 4

- Intuitive, factory installed microprocessor-based controller compatible with BACnet®, Modbus®, and LonTalk®

- Standard uncoated or optional e-coated microchannel heat exchanger (MCHE) condenser coils

- Highly efficient, dual circuit brazed plate heat exchangers offer maximum performance at both full and part-load conditions

- Operation from -20°F to 115°F (-29°C to 49°C) ambient temperature as chiller

- Galvanized steel frame with painted finish on exterior panels minimizes corrosion and promotes long equipment life

- Integral variable speed pumps available for standalone units and pump skids for array assemblies

- R-454B available

- UL 60335 compliant for R-454B refrigerant

Applications

- High capacity evaporators are available for 40°F (4°C) leaving water applications or for applications requiring glycol to offset capacity reduction of glycol system.

- Constant or variable primary flow systems with factory installed motorized or manual valve packages.

- Ice making mode available for skating rinks, thermal storage and more.

- Heat recovery capability up to 140°F (60°C) to conserve energy by using second condenser to provide leaving water to serve heat loads like boiler loops, reheat coils, and more.

- The flexible design of Jetson chillers allows applications in both process and comfort cooling applications.

Array of (3) 50-ton modules Resources

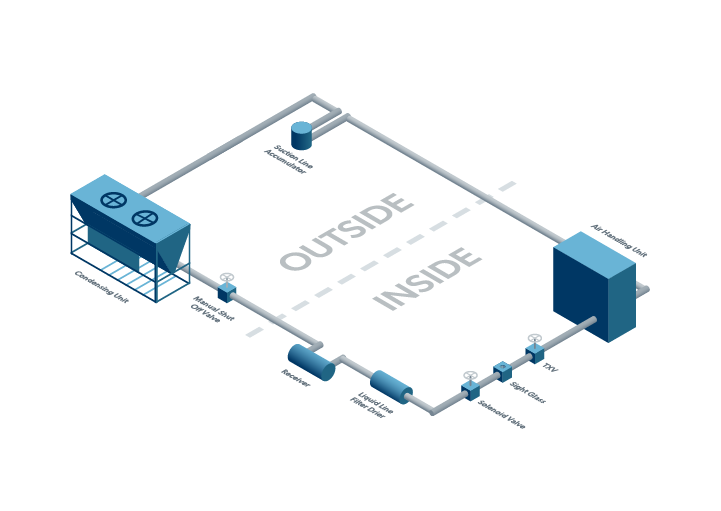

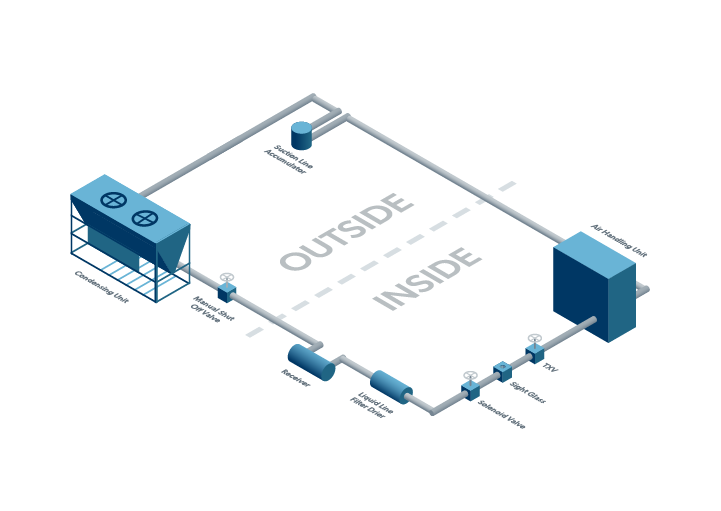

- Split-System Air-Cooled Chillers and Condensing Units

Features & Options

- Capacities from 10 to 85 tons

- Indoor unit is designed for easy retrofit—fits through a standard three-foot door

- Brazed plate or shell and tube evaporator to match your chilled water needs

- Intuitive, factory installed microprocessor-based controller compatible with BACnet®, Modbus®, and LonTalk®

- Labeled control wiring matches unit wiring diagram included in the control compartment

- The remote evaporator option available on condensers with compressors allows chilled water to be generated remotely

- Split systems are available with a number of options including, suction, liquid and discharge service valves, corrosion protected coils, vibration isolators and more

- Compressor acoustic hoods and/or sound isolating cabinets are available for sound sensitive applications

- Replaceable core filter driers for ease of service and installation of split system piping

- LED lighted control cabinet for clear viewing during service and maintenance

- 15.4” Touchscreen for viewing machine performance and easy access for service and maintenance personnel

- Predetermined refrigerant line sizes for quick and easy field installation

- Available with compressor(s) indoor at evaporator in compressor chiller configuration or with compressor(s) outdoor at condenser in condensing unit configuration

- R-454B available

Applications

- High capacity evaporators are available for 40°F (4°C) leaving water applications or for applications requiring glycol to offset capacity reduction of glycol system.

- With the evaporator indoors, no freeze protection is required. This has the benefits or requiring no glycol, no draining of the system, and no need to run pumps all winter long.

- With the evaporator AND compressors indoors, no freeze protection is required and additional components that were outdoors, such as the unit controller, are located indoors for ease of maintenance.

Resources

- Air-Cooled Condensing Units

Features & Options

- Capacities from 10 to 90 tons

- High-efficiency scroll compressors.

- Intuitive, factory installed microprocessor-based controller compatible with BACnet®, Modbus®, and LonTalk®

- Standard uncoated or optional e-coated microchannel heat exchanger (MCHE) condenser coils

- Galvanized steel frame with painted finish on exterior panels promotes long equipment life.

- High and low-pressure protection/compressor overload protection

- Ground or rooftop installation

- Compressors are factory installed on rubber isolation mounts for quiet operation

- Compressor acoustic hoods and/or sound isolating cabinets are available for sound sensitive applications

- Variable speed condenser fans

- R-454B available

- UL 60335 compliant for R-454B refrigerant

Applications

- Multi-story office buildings, hotels, schools, municipal and industrial facilities that need economical cooling but cannot utilize equipment like rooftop units benefit from split system designs.

- The air-cooled condensing unit installs easily and quickly on the roof or ground and refrigerant line sizes are predetermined for typical comfort cooling and process applications.

- With the evaporator indoors, no freeze protection is required. This has the benefits or requiring no glycol, no draining of the system, and no need to run pumps all winter long.

- Condensing units are flexible and can be matched with indoor brazed plate, shell and tube or DX fin and tube evaporators.

Resources

- Packaged Water-Cooled Chillers

Features & Options

- Capacities from 20 to 75 tons

- Intuitive, factory installed microprocessor-based controller compatible with BACnet®, Modbus®, and LonTalk®

- High efficiency scroll compressors as standard and optional variable speed compressor on the lead circuit for a lower turndown

- Brazed plate evaporators and robust cleanable shell-and-tube condensers are uniquely suited for open loop cooling tower applications

- Heat Recovery capability up to 140°F (60°C) to conserve energy by reusing condenser leaving water to serve heat loads like boiler loops, reheat coils and more

- Available as compressor chiller (CCAC) to be paired with a remote air-cooled or a water-cooled condenser

- Available as water-cooled condensing unit (WCCU) for DX applications.

- Dual circuit refrigeration systems for greater operating redundancy

- Compressors are factory installed on rubber isolation mounts for quiet operation

- Compressor acoustic hoods and/or sound isolating cabinets are available for sound sensitive applications

- Designed for easy retrofit—fits through a standard three-foot door

- Built-in R-454B refrigerant leak detectors and an enclosure that improve the precision of the detection system

Applications

- Ideal for comfort cooling, low-temperature process cooling, and ice-making. It’s perfect for educational and healthcare facilities, office buildings, municipal, and light industrial settings.

Resources

- Air-Cooled Compressor Chiller

Features & Options

- Capacities from 20 to 75 tons

- Dual circuit refrigeration systems for greater operating redundancy

- Intuitive, factory installed microprocessor-based controller compatible with BACnet®, Modbus®, and LonTalk®

- Evaporator brazed plate and high efficiency scroll compressors as standard

- Compressors are factory installed on rubber isolation mounts for quiet operation

- Compressor acoustic hoods and/or sound isolating cabinets are available for sound sensitive applications

- Designed for easy retrofit—fits through a standard three-foot door

- Factory charged with dry nitrogen

- Designed for seamless integration with Jetson ACCR (Air-Cooled Condensers)

- Built-in R-454B refrigerant leak detectors and an enclosure that improve the precision of the detection system

Applications

- Ideal for comfort cooling, low-temperature process cooling, and ice-making. It’s perfect for educational and healthcare facilities, office buildings, municipal, and light industrial settings.

Resources

- Modular Water-Cooled Chillers

- Employment

Employment Opportunities

As a leader in our industry, we are committed to providing a safe, wholesome workplace and to the development and training of its employees. Jetson pays top wages for its employees and offers a full complement of benefits which include:

- 401(k) Plan

- Healthcare, Dental, and Life Insurance

- Chaplain Care Service

- Company Paid Holidays

- Paid Time Off

Because we are continually growing and expanding, we are looking to hire talented personnel. If you believe you have the drive, focus, and determination to join our team and take us further up the ladder of success, please respond to the current posting below.

Open Positions

Please look back for any opportunities after the integration of Modine Manufacturing and Jetson.

- Sales

- Resources

Browse our resources below to find the information you need from product information to installation manuals and more.

Product Brochures – Browse our complete product line to find the right air-cooled & water-cooled chillers and more

Installation Manuals – Find your product’s manual for installation, operation, and maintenance support

Product Catalogs – Download our library of product catalogs to get in-depth specifications to find the right Jetson product

Product Brochures

Complete Product Line

Whitepapers and Individual Product Brochures

Air-to-Water Heat Pumps Application Guide (JET17-300.1)

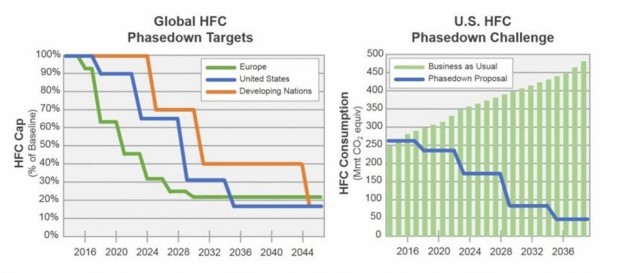

Air-to-Water Heat Pumps Application Guide (JET17-300.1)Download PDF  Jetson transition into R-454B refrigerant (Updated 08/2024)

Jetson transition into R-454B refrigerant (Updated 08/2024)Download PDF  10-800 ton; Model ACCA – Modular Air-Cooled Chillers

10-800 ton; Model ACCA – Modular Air-Cooled ChillersDownload PDF  20-600 ton; Model FWCD – Modular Water-Cooled Chillers

20-600 ton; Model FWCD – Modular Water-Cooled ChillersDownload PDF  10-90 ton; Split System Chiller Systems

10-90 ton; Split System Chiller SystemsDownload PDF  10-90 ton; Model ACCU – Air-Cooled Condensing Units

10-90 ton; Model ACCU – Air-Cooled Condensing UnitsDownload PDF  20-75 ton; Model WCCU – Water-Cooled Condensing Units

20-75 ton; Model WCCU – Water-Cooled Condensing UnitsDownload PDF Installation Manuals

10-90 ton; Model ACCA- Packaged Air-Cooled Chillers

10-90 ton; Model ACCA- Packaged Air-Cooled ChillersDownload PDF  10-600 ton; Model ACCA – Modular Air-Cooled Chillers

10-600 ton; Model ACCA – Modular Air-Cooled ChillersDownload PDF  20-600 ton; Model FWCD – Modular Water-Cooled Chillers

20-600 ton; Model FWCD – Modular Water-Cooled ChillersDownload PDF  10-80 ton; Split System Chiller Systems

10-80 ton; Split System Chiller SystemsSplit systems are comprised of:

Compressor chiller (evaporator, compressor(s), controls) paired with remote condenser

OR

Condensing unit (condenser, compressor(s), controls) paired with remote evaporator

(See corresponding installation manuals in this section) 10-90 ton; Model ACCU – Air-Cooled Condensing Units

10-90 ton; Model ACCU – Air-Cooled Condensing UnitsDownload PDF  20-75 ton; Model WCCU – Water-Cooled Condensing Units

20-75 ton; Model WCCU – Water-Cooled Condensing UnitsDownload PDF Product Catalog

10-90 ton; Model ACCA- Packaged Air-Cooled Chillers

10-90 ton; Model ACCA- Packaged Air-Cooled ChillersDownload PDF  10-800 ton; Model ACCA – Modular Air-Cooled Chillers

10-800 ton; Model ACCA – Modular Air-Cooled ChillersDownload PDF  20-75 ton; Model WCCP – Packaged Water-Cooled Chillers

20-75 ton; Model WCCP – Packaged Water-Cooled ChillersDownload PDF  20-600 ton; Model FWCD – Modular Water-Cooled Chillers

20-600 ton; Model FWCD – Modular Water-Cooled ChillersDownload PDF  10-80 ton; Split System Chiller Systems

10-80 ton; Split System Chiller SystemsSplit systems are comprised of:

Compressor chiller (evaporator, compressor(s), controls) paired with remote condenser

OR

Condensing unit (condenser, compressor(s), controls) paired with remote evaporator

(See corresponding catalogs in this section) 10-90 ton; Model ACCU – Air-Cooled Condensing Units

10-90 ton; Model ACCU – Air-Cooled Condensing UnitsContact Jetson  20-75 ton; Model WCCU – Water-Cooled Condensing Units

20-75 ton; Model WCCU – Water-Cooled Condensing UnitsDownload PDF Jetson Terms of Sale:

- About Us

Teamwork

We act as a team,

with each other

and our customers.

We help each

other succeed and

celebrate our wins.Trust

We do what we say

we will do.Focus

We believe things

that matter most

should never be at

the mercy of the

things that matter

least. We focus our

energies on high

return activities.Family

We support the role

that family plays in

our lives. We work

safely for those we

care about and for

those that care

about us.Continuous

ImprovementWe continuously

pursue excellence

in ourselves, our

company and the

products and

services that we

deliver.Communication

We communicate to

coordinate our actions.

We actively listen in our

communication to first

understand, then to be

understood.About Us

Over the next few months, we will be working to merge the Jetson product line into the Modine Manufacturing portfolio. Napps Technology (also known as “Jetson”) is a leading provider of low-capacity Air and Water Cooled Chillers, Condensing Units and Heat Pumps in North America. Jetson is a leading innovator and provider of advanced, high-quality air conditioning and heating solutions for commercial and industrial applications. Our core values guide us to continuously strive for excellence as a leading HVAC manufacturer

Our Vision

Jetson is an engineering driven manufacturer of Water-Cooled Chillers, Air-Cool Chillers, and Condensing Units. With years of experience in all phases of the HVACR industry, we are committed to developing and manufacturing products that are highly efficient, reliable, serviceable and cost effective.

The full line of Jetson, highly efficient commercial products are offered exclusively through our representatives. These products range in capacity from 10 to 600 tons

- Contact Us

- Sitemap

- Sign Up for the Jetson HVAC Newslettervar _ctct_m = “95fb072aaf4c81244a440b5776507400”;